SPC Flooring Manufacturer

Wholesale SPC Flooring, customizable with your logo, available factory direct from China.

What is SPC Flooring

SPC Flooring (Stone Plastic Composite Flooring)

is a type of rigid core vinyl flooring known for its durability, moisture resistance, and ease of installation.

It is made from a combination of natural limestone powder, polyvinyl chloride (PVC), and stabilizers, which create a solid, dense core that offers several advantages over traditional vinyl flooring.

SPC Flooring Advantages

100% Waterproof

SPC flooring is completely waterproof, making it ideal for moisture-prone areas like kitchens and bathrooms.

Durable

It is highly durable, resistant to scratches, stains, and heavy foot traffic.

Stability

The rigid core provides excellent dimensional stability, preventing warping or expansion.

Realistic Designs

SPC flooring comes in a variety of high-definition designs that mimic natural wood, stone, and tile.

Easy Installation

It features a click-lock system for quick and easy installation without the need for glue or nails.

Low Maintenance

SPC flooring is easy to clean and requires minimal upkeep.

Sound Insulation

SPC products come with an underlayment that reduces noise and adds IXPE comfort.

ECO-Friendly

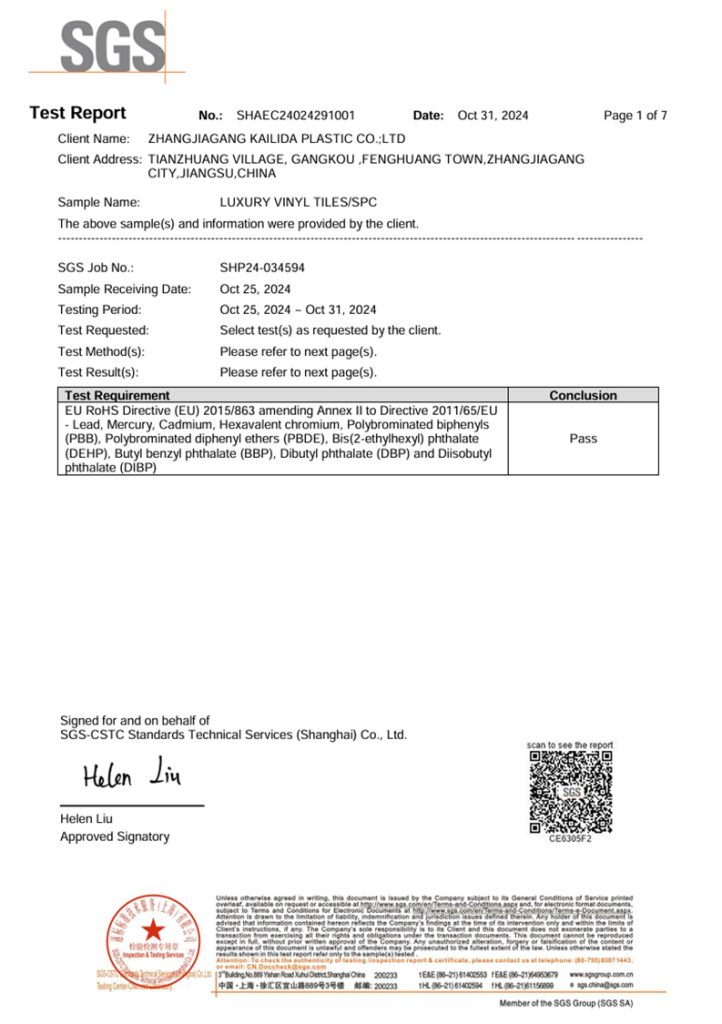

Made from non-toxic materials, SPC is a safe and eco-friendly flooring choice

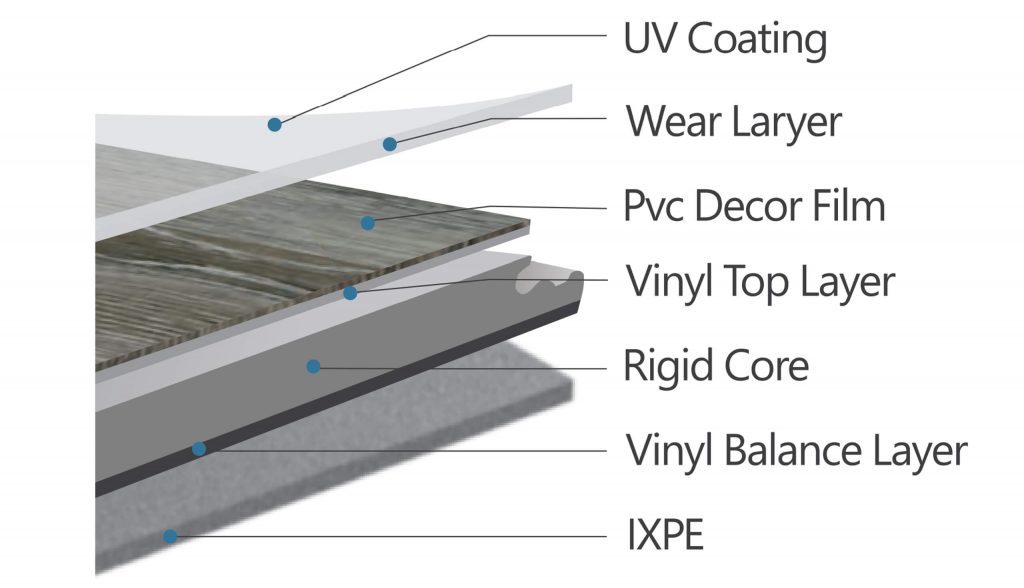

SPC Flooring Structure

1. UV Coating

Enhances the clarity of the decorative film while providing resistance to fading, keeping your floors looking fresh.

2. Wear Layer

Offers excellent scratch resistance and durability, making SPC flooring ideal for high-traffic areas like homes and shopping malls, with a lifespan of over 20 years.

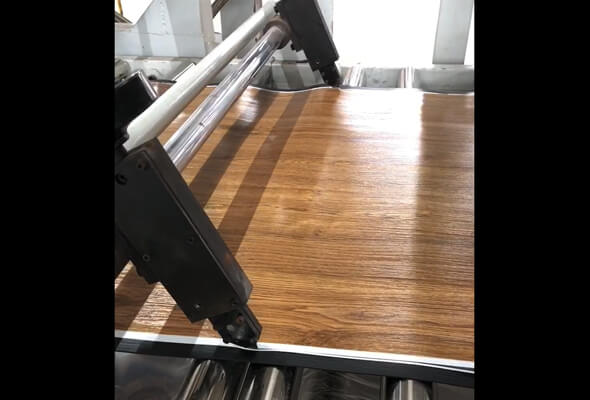

3. Decorative Film

Features modern, stylish designs that reflect the latest trends and popular looks in the flooring market.

4. SPC Rigid Core

Constructed from a fine stone-plastic composite material, giving the flooring strength and stability.

5. Underlayment (Optional)

Optional IXPE or EVA underlayment boosts grip, enhances comfort, reduces noise, and adapts well to existing surfaces.

6. Click-Lock Installation

The easy-to-use click-lock system ensures quick installation while making the floor sturdy, waterproof, and long-lasting.

SPC Flooring Data

| Dimensions(“) | Dimensions(mm) | Thickness(mm) | Wear Layer Thickness(mm) | IXPE |

| 7×48″ 7.17×48″ 6×36″ 9×48″ | 180×1220 182×1220 152.4×914.4 228×1220 | 3.6 | 0.3 | 1.0mm/1.5mm |

| 4.0 | 0.3/0.5 | 1.0mm/1.5mm | ||

| 4.2 | 0.3/0.5 | 1.0mm/1.5mm | ||

| 4.5 | 0.3/0.5 | 1.0mm/1.5mm | ||

| 5.0 | 0.3/0.5 | 1.0mm/1.5mm | ||

| 5.5 | 0.3/0.5 | 1.0mm/1.5mm | ||

| 6.0 | 0.3/0.5 | 1.0mm/1.5mm |

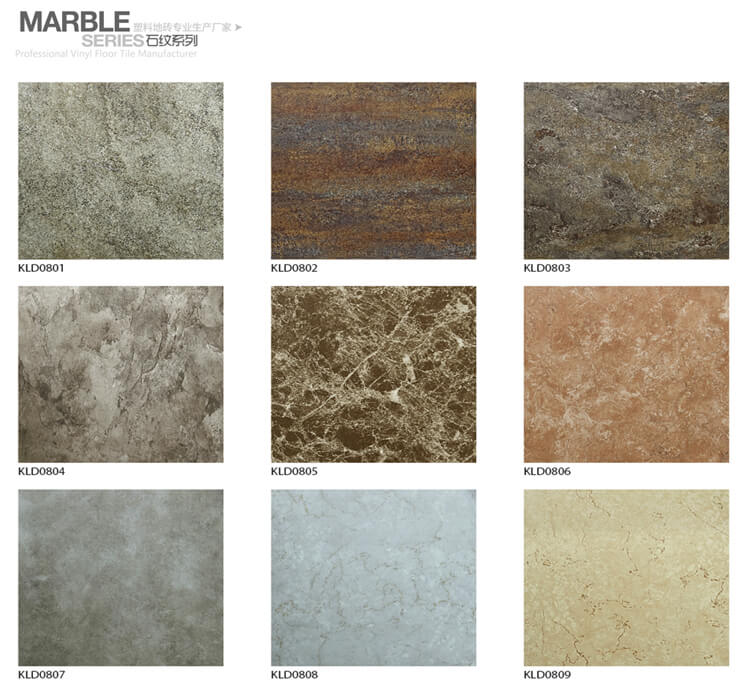

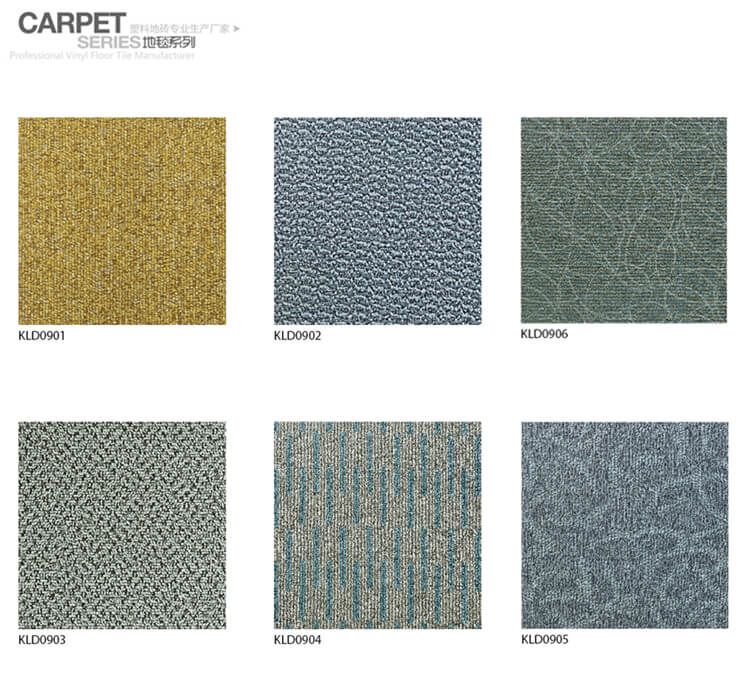

SPC Flooring Patterns

SPC flooring offers a wide range of colors and patterns, including wood, marble, and carpet designs, making it easy to choose a style that suits your business and project needs.

Marble

Carpet

Wood

SPC Flooring Installation Guide

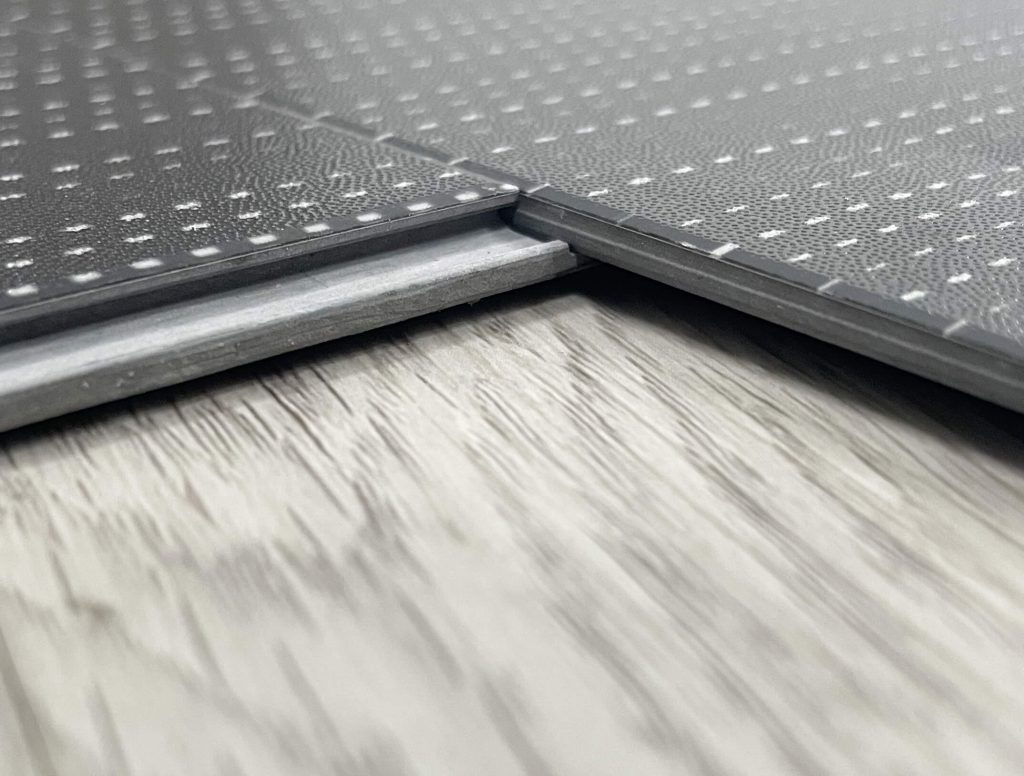

Unilin Click-Lock System

The Unilin click-lock system is a simple, easy-to-install solution that ensures a secure connection between planks:

- Structure: Each plank has a groove on one side and a tongue on the other.

- Installation: To install, you just align the tongue with the groove and press down until it clicks into place, securing the planks together.

- Advantages: This system provides a tight, reliable fit without needing glue or nails. It’s also waterproof, making it durable and ideal for various spaces.

- Best For: It’s a great option for both residential and commercial spaces where ease of installation is key.

Valinge Click-Lock System

The Valinge system is a more advanced locking mechanism that offers extra stability:

- Structure: It features a top-locking mechanism that locks planks both horizontally and vertically.

- Installation: To install, the tongue is inserted into the groove and pressed down to lock. This system secures the planks in both directions, ensuring a firm and durable fit.

- Advantages: With its multi-directional lock, the Valinge system offers enhanced strength and stability, making it especially useful for high-traffic areas.

- Best For: This system is perfect for commercial spaces or areas with heavy foot traffic, where added durability is required.

Applications For SPC Flooring

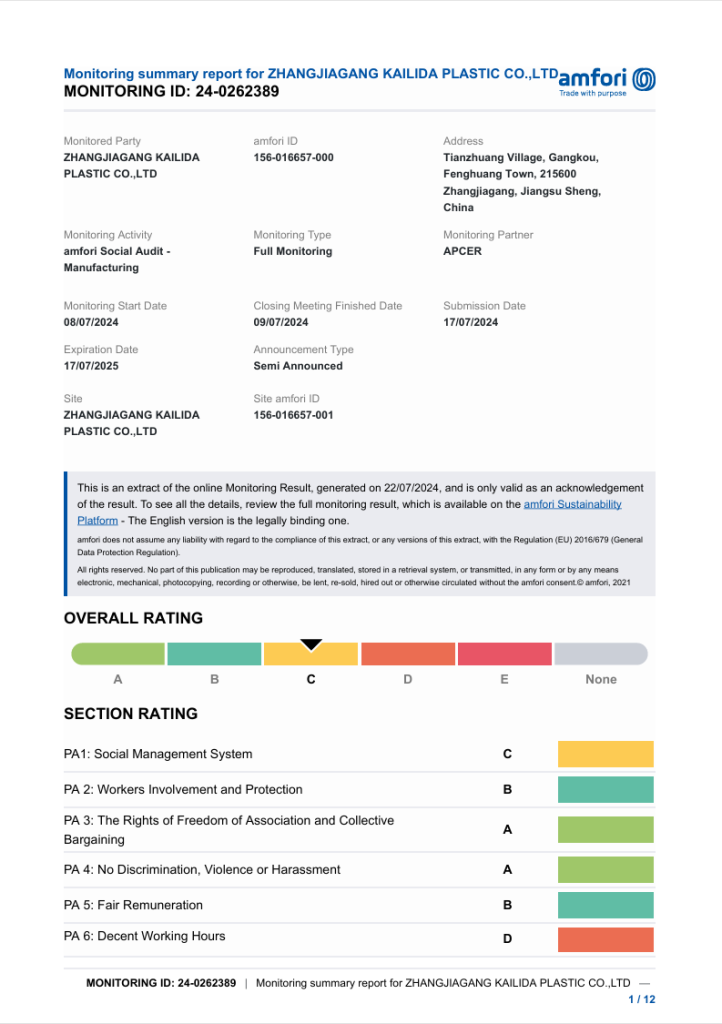

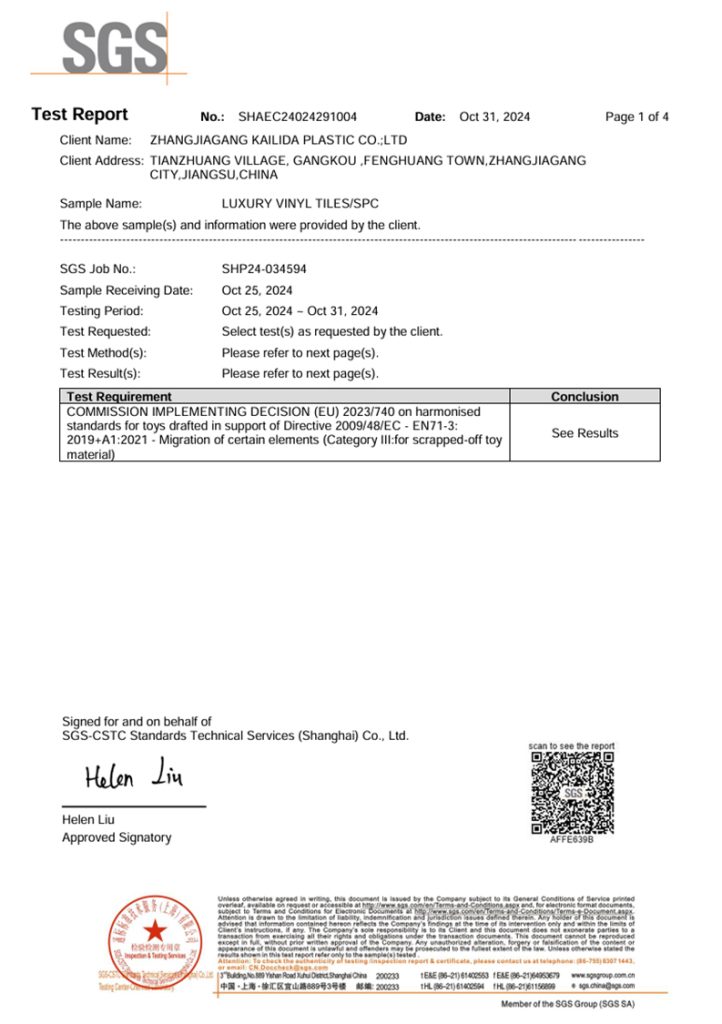

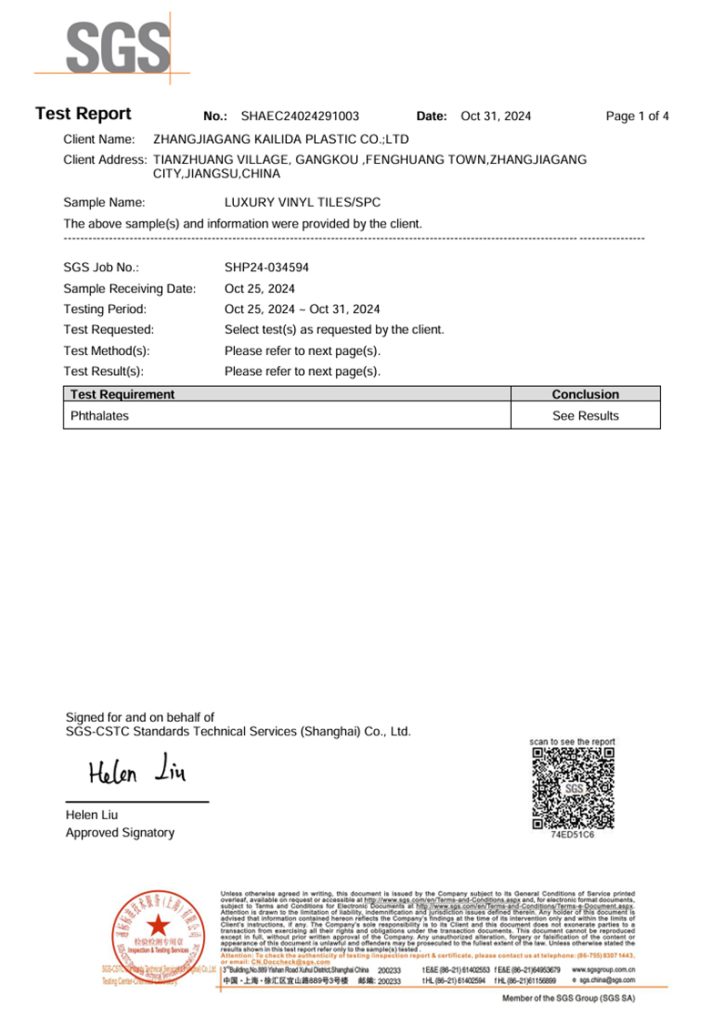

Our Certifications

Our Factory

Mixing System

- The first step is feeding. The raw materials are put into the mixer in proportion to the formula.

- Other processing aids need to be measured separately and mixed together then put into the feeding station and sucked into the feeding tank by a vacuum feeder.

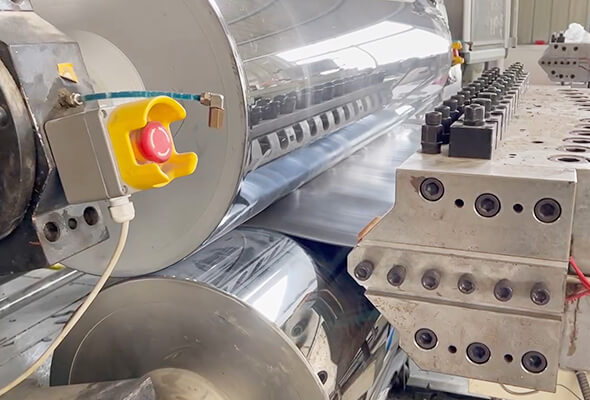

Extrusion System

- After entering the screw barrel, the materials are plasticized by heated rolling. In this process, temperature control is the most critical link.

- After the completion of plasticizing, the materials will be extruded, and then pushed to the tooling by strong back pressure. The tooling size is determined by product specifications.

- The material strap comes out of the tooling opening and then enters the five-roller calendering system.

Tractor

The tractor of the floor production line adopts the structure of frequency conversion, speed regulation, and motor direct connection, which can match the production line speed perfectly.

Shearing Machine

- The material strap is transported to the shearing machine, by the tractor for cross-cutting.

- For the cutting length, the signal is transmitted by the photoelectric switch, so that the response, can be sensitive and the length can be accurate.

Automatic Platen Machine

The finished material strap, after being cut, will be stacked by an automatic platen machine.

Floor Grooving Line

After the floor cutting is completed, it enters the grooving line for grooving processing.

Package

Usually packaged in colour boxes. 8 pcs/set, 65sets/pallet, 20 pallets(2284㎡) /20GP

Container Loading

Use of forklifts, loading of containers, and dispatch of goods according to customer requirements.

Packing Reinforced

The use of wooden pallets and professional reinforced packaging ensures safe transportation to the client.

How to Order

01: OEM Customization

We offer flexibility in customizing your flooring products. Choose the appropriate wear layer thickness, select your preferred rigid-core thickness, and pick from a variety of vibrant textures. Underlayment options are also available to meet your specific needs.

02: Free Samples

We provide FREE samples for your evaluation. You can select from our stock samples or request customized options to ensure the perfect fit for your project.

03: Payment Terms

Our standard payment terms are 30% T/T in advance, with the remaining 70% due before shipping. We also accept L/C at sight for added convenience and security in your transactions.

04: Bulk Production

Once the samples are approved, we initiate bulk production. Our state-of-the-art production lines ensure high quality and timely delivery, meeting both your quality standards and lead-time requirements.

05: Quality Control & Packaging

Each floor undergoes rigorous inspection before shipment. Only after meeting our strict quality standards are the products carefully packaged and prepared for dispatch.

06: Shipping & Delivery

We partner with trusted shipping companies to ensure that your order is delivered quickly and efficiently, so you can receive your flooring products within the shortest possible time frame.

What Our Customers Say

During the whole process of purchasing, CF made me feel very safe. Their salesman was very professional. At the same time, I was so satisfied with their service.

Robert Morita

I never get my LVT flooring wholesale from other supliers only, besides the CF because it is the only I trust in China, my colleague has personally visited their factory and was impressed with their advanced equipment. I'm willing to import glue-down flooring from their company. One more thing, my consumers are not resistant to having good quality lvt flooring, so I have high expectations of the supplier's control quality capabilities, but CF never disappoints me.

Jack Lewis

From the beginning of contacting your company, after several months of negotiations, we finally reached cooperation. CF’s vinyl floors are very popular, and the quality and price are very good, which has kept my business hot, and I have recently ordered thirty 40-foot cabinets. Thank you for your sincerity and I hope that our cooperation is happy.

Felicity Trump

Frequently Asked Questions

Yes, we provide free samples for you to evaluate. You can choose from our stock samples or request a custom sample to suit your needs.

Yes, we offer OEM and ODM services. You can customize the design, size, texture, and branding according to your requirements.

- Payment methods: T/T and L/C

- Trading methods: FOB and CIF

The MOQ for SPC flooring is typically 2000 square meters. one 20-foot cabinet. We can discuss flexibility depending on your specific needs.

Our standard sample time is about 3~7 days, delivery time is typically between 30 and 45 days, depending on order size and customization.

We will provide you with a tracking number after shipment, so you can monitor the progress of your order at any time.

Our flooring undergoes strict quality control procedures, including inspection of raw materials, in-process checks, and final product testing to ensure consistency and durability.

We pack our products carefully to ensure safe transport. Standard packaging options include color box, shrink wrapping, wooden pallets, or customized packaging solutions.

We provide detailed product specifications, images, and sample approval for every order, ensuring the final product meets your expectations.

We offer a warranty of 10 to 25 years on our SPC flooring, depending on the specific product line and its intended use.